The tapered conical wine fermenter is a stainless steel tank designed for the production of red wines. It will appeal to those who prefer doing pigéage manually rather than automatically. Using some additional equipment, it can additionally be adapted for maceration, fermentation and clarification of white wines.

The conical wine fermenter keeps its temperature very well, thanks to the thermally-inert tapered shape. The conical shape also makes punching the pomace cap down (pigéage) easier. This particular stainless steel wine tank comes with a large manhole on the center of its head that provides quick and comfortable access for the punch-down process.

You can outfit the tapered conical wine fermenter with a pump-over system, enabling the use of pump-over winemaking techniques such as remontage and délestage. The large discharge valve at the very bottom of the tank is perfect for attaching a pump. This turns the conical wine fermenter into a truly versatile, all-in-one winemaking powerhouse.

To make cleaning the tank after vinification easier, it's equipped with a large, square manway door perfectly aligned to the straight, sloped bottom. Raking up the leftover pomace has never been simpler. A large mesh screen is mounted to the tank wall just beneath the discharge valve, preventing that same pomace from clouding your wine.

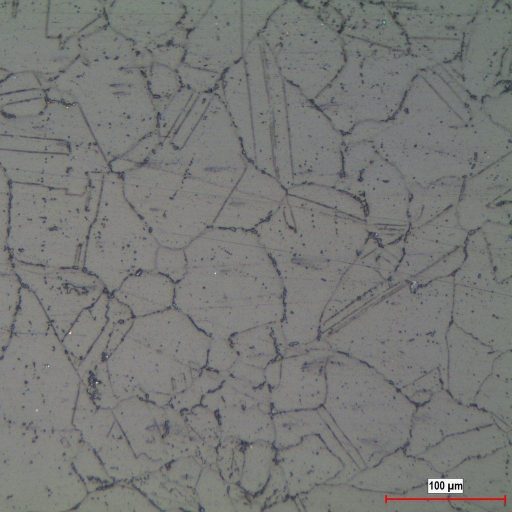

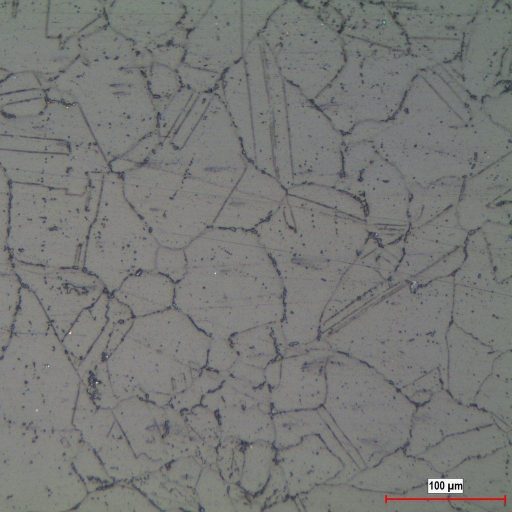

The tapered fermenter is made out of AISI 304 quality stainless steel. An upgrade to AISI 316L stainless steel is available for high-corrosion environments.

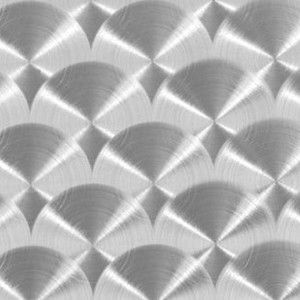

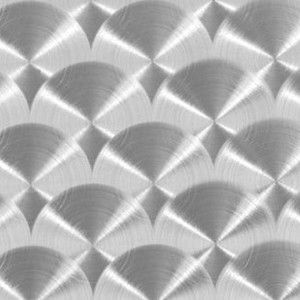

A high-polish, marbled finish is applied to the outside of the tapered fermentation tank. Matte and Scotch Brite finishes are also available upon request. The inside is BA (IIId) polished.

The tronco-conical wine fermentation tank comes with a flat, sloped bottom. Paired with the large, rectangular door, the discharge of the sloped tank is made easy.

![[Bottom] Sloped](https://letina.com/wp-content/uploads/tank-parts-bottoms-b4-sloped.jpg)

![[Bottom] Sloped](https://letina.com/wp-content/uploads/tank-parts-bottoms-b4-sloped.jpg)

![[Top] Conical Centric](https://letina.com/wp-content/uploads/tank-parts-tops-t3-conical-centric.jpg)

![[Top] Conical Centric](https://letina.com/wp-content/uploads/tank-parts-tops-t3-conical-centric.jpg)

The tapered shape makes punching the pomace cap down (pigéage) easier. It is also thermally inert, allowing the tank to hold its temperature well.

The rotating HELI sprinkler can be mounted on the tapered fermenter's head. It efficiently soaks the entire layer of pomace in the wine tank.

Pneumatic devices can be installed on the bottom of the tank. They send short bursts of air, creating bubbles. The bubbles rise to the top, delicately mixing the liquid in the vessel.

Rotating blades can mounted to the bottom of the tronco-conical wine tank, which gently push the leftover pomace out of the rectangular doors, automating discharge.

The wine fermentation tank can be equipped with a programmable, touchscreen control panel. It can regulates the pump and temperature inside the tank, allowing you to automate the entire process.

Manhole Cover – Round Ø600 mm

Manway Door – Rectangular (type Z1500)

Legs – Standard (Closed)

Temperature Control

Cooling Jacket (1 m2/1000 L)

Thermometer (analog)

Thermowell (with PG9 fitting)

Valves

Sample Tap (DN15)

Partial Discharge – Ball valve (DN32 DIN11851)

Total Discharge – Ball valve (DN65 DIN11851)

Vent Valve – DN50 (PVC)

Mesh Screen

Level Indicator – Ø16 mm acrylic tube (scaled, open)

Type Plate – With note card

Ladder Support – Coat height 1500 mm onwards

Welding – Brushed finish

HELI Rotating Sprinkler

Pipe – DN32 DIN11851 (with fitting)

Pump (for pumping over)

Cip Ball

Automatic Pomace Discharge

Automatic Pulsation Devices/AirPlus (or fittings only)

Control Panel (touchscreen) – Temperature and Pump Control

Manway Door

Custom sizes

Additional oval door (on hinge)

Legs – Adjustable height and tilt

Temperature Control

Heating Jacket

Cooling Jacket (>1 m2/1000 L)

Electric heater with bath on bottom

Digital thermoregulator with temperature control

Valves

Ball or butterfly (Clamp, Garolla, WG, Macon, Gas, etc.)

Electromagnetic or electromotor valves

Stainless steel caps (on all valves and fittings)

Fittings

Inclined stirrer fitting

Inert gas fitting

Level Indicator – Ø24 mm acrylic tube (scaled, closed)

Decanter

Welding – Brushed and polished (Ra<0.8 µm)

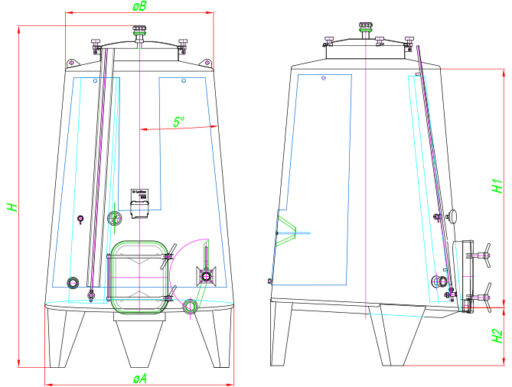

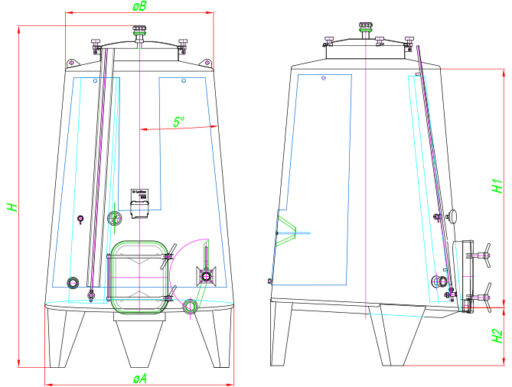

| Type | Volume | ØA | ØB | H1 | H2 | H |

|---|---|---|---|---|---|---|

| VIKC1250A11 | 1250 | 1115 | 818 | 1700 | 500 | 2550 |

| VIKC1850A13 | 1850 | 1275 | 943 | 1900 | 500 | 2750 |

| VIKC2500A14 | 2500 | 1402 | 1026 | 2150 | 500 | 3000 |

| VIKC3600A16 | 3600 | 1593 | 1180 | 2360 | 500 | 3230 |

| VIKC4800A18 | 4800 | 1752 | 1297 | 2600 | 500 | 3500 |

| VIKC6200A19 | 6200 | 1911 | 1416 | 2830 | 500 | 3720 |

| VIKC7850A21 | 7850 | 2071 | 1538 | 3050 | 500 | 3950 |

| VIKC9850A22 | 9850 | 2230 | 1653 | 3300 | 500 | 4220 |

| VIKC12050A24 | 8500 | 2389 | 1773 | 3520 | 500 | 4450 |

| VIKC14500A25 | 14500 | 2501 | 1810 | 3950 | 500 | 4880 |